HISTORICAL REVIEW

Company founder Albin Göpfert

1950

FOUNDATION OF THE COMPANY

On Sunday, 1 February 1920, Albin Göpfert was born to Lioba and Josef Göpfert. His father worked as a small-scale farmer and wood raftsman. Albin had no intention of following in his father‘s footsteps. At the age of 14, he decided to train as a mechanical engineer. In 1950, after successfully completing his master‘s examination in mechanical engineering, he was entered in the register of craftsmen of the Chamber of Crafts for Lower Franconia and was henceforth entitled to ‘hold the title of master craftsman and train apprentices.’ In the post-war period, like so many others, he was hit hard by unemployment. So he set up his own business and earned his living with small jobs in his one-man repair shop. His motto was: ‘Never shy away from work.’ Whatever needed to be done, he did. He made wrought-iron railings, repaired tractor seats, built consoles and practiced his skills in the construction of small mechanical devices, for example for a weaving mill. It didn‘t take long for him to realize that he was particularly good at this task. Over the next few years, his work shifted more and more towards the construction of devices with special requirements. To save money, Albin invested in a simple, cheap lathe. This turned out to be a mistake, as it later became apparent. However, it taught him early on that only quality pays off.

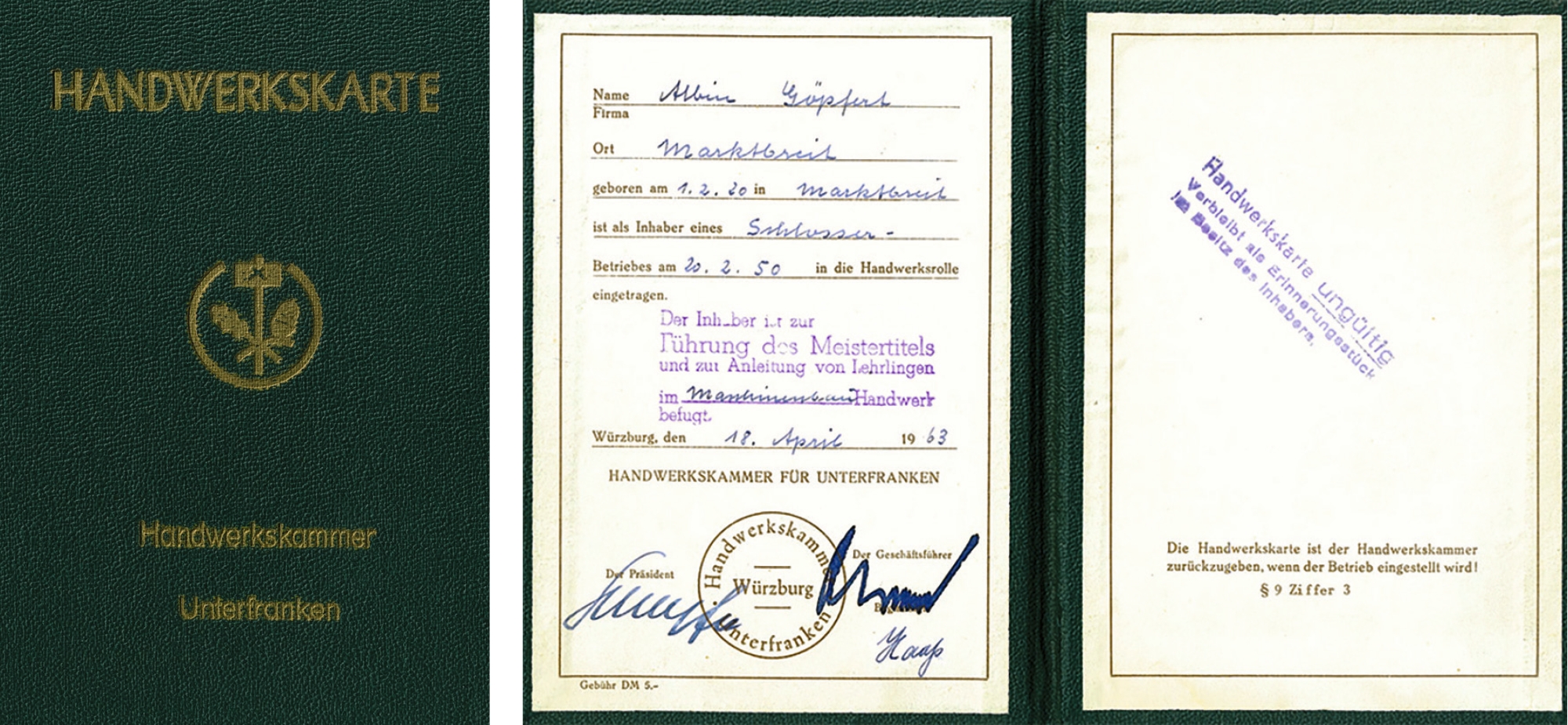

Albin Göpfert‘s craftsman‘s license from 1950 is the earliest written evidence of him practicing his profession.

1952

SPECIALISATION IN MECHANICAL ENGINEERING

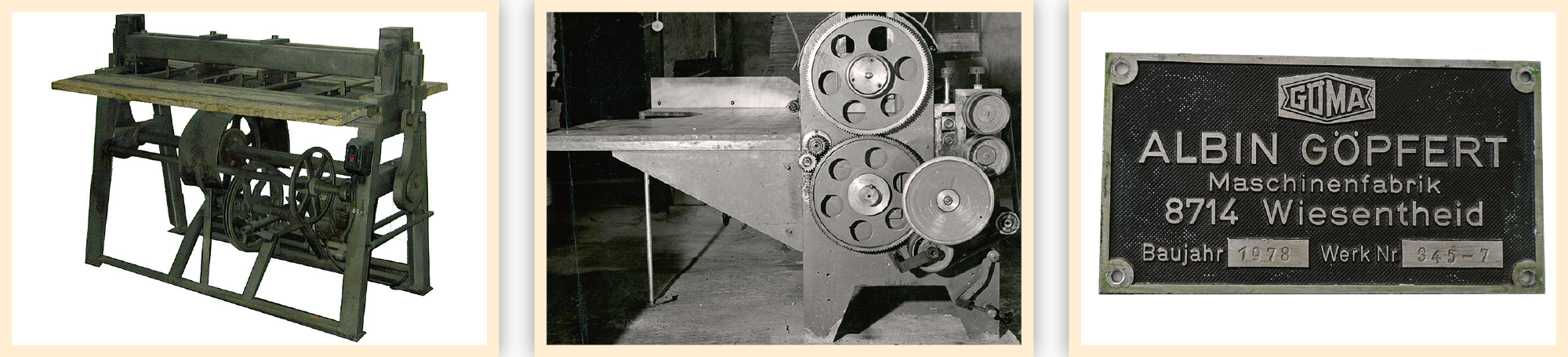

From left to right: First bridge die cutter, hand slotting machine for REKA, first GÖMA company logo.

When Albin Göpfert founded his machine shop, corrugated cardboard was not yet a working material. However, there was a small cardboard factory in Marktbreit. Its owners, the Schröder family, commissioned Albin to make a special design. So in 1952, he built his first bridge die cutter for corrugated cardboard from parts he had collected. One of the family‘s sons, Heinrich Schröder, who had also started his own corrugated cardboard business and founded his own cardboard factory called REKA in the Lohof district of Munich, took note of the machine and commissioned Albin Göpfert to further develop it and produce several replicas. This was hardly surprising: the design was simple, powerful, robust and, what was particularly important at the time, inexpensive to produce. REKA used the machines at its corrugated cardboard factory in Kitzingen. Göpfert was subsequently also employed there to repair and modernize individual machines. With this first major customer, the company, which had been founded in a barn, emerged from obscurity and began to grow. Further examples of the machine were produced, which quickly found their way into other factories, soon spreading beyond the Franconian region. Albin began to tinker with new machine designs and delivered his first rotary slitting machine in 1953. To ensure that everyone would recognize the machines, Albin registered the brand name ‘GÖMA’, designed a company logo and affixed it to the machines.

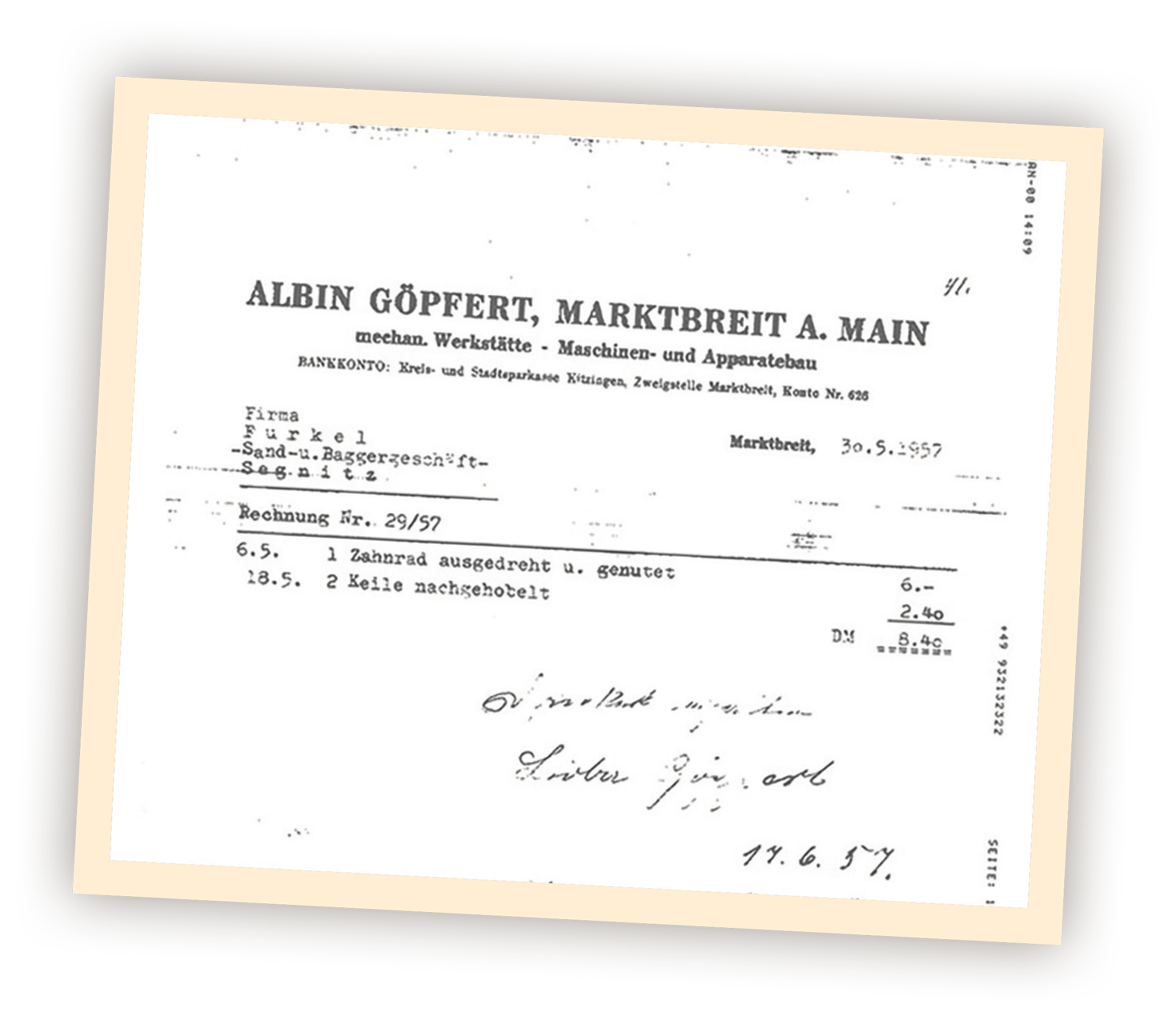

Invoice from 1957.

1960

CONSOLIDATION DURING THE ERA OF THE ECONOMIC MIRACLE

The 1950s brought new energy to the German economy and boosted consumer spending. The young company was also set to benefit from this, as the ever-increasing number of products produced during the economic miracle had to be packaged somehow – and cardboard boxes were the ideal solution. Nevertheless, during the years of the economic miracle, the Göpfert company showed signs of stagnation, as evidenced by the number of employees, which remained constant at six throughout the 1960s. Albin Göpfert soon dreamed of expanding – away from the simple goat shed – but he simply lacked the financial means. It was only when a private bank granted him a loan that Albin Göpfert decided to build a new residential building with a hall in Marktbreit. This laid the foundations for growth. In 1960, the hall in the Marktbreit industrial estate on Mainleite was ready for occupancy and went into operation. Here, there was enough space for a new level of creativity and production. The portfolio could now be expanded and new special machines for corrugated cardboard processing developed.

Title page of a catalogue from 1968, at that time still featuring the first company logo ‘GÖMA’.

1969

JOINING THE COMPANY KARL F. GÖPFERT

In 1969, at the age of 22, Karl F. joined the company after completing his mechanical engineering studies at the Polytechnic University in Schweinfurt. Before that, he had completed an apprenticeship as a machine fitter in his parents‘ company and subsequently earned his technical college entrance qualification. International placements allowed him to further deepen his expertise in corrugated board processing machines.

Karl F. Göpfert at the age of 22 years.

A proud pioneering achievement: Albin and Karl F. Göpfert inspecting the journeyman‘s piece, the ‘KS’, an innovative creasing and cutting machine that the son had made at the end of his apprenticeship.

From the outset, Karl F. concentrated on optimizing the organization and expanded the team by hiring technical designers and skilled workers – a step that didn’t always meet with his father’s full approval. Also in 1969, he married Siglinde Schermer. Their marriage was blessed with a daughter, Esther, and a son, André. From the very beginning, Siglinde stood by her husband's side and supported him in all business matters.

1972

INTERNATIONAL BREAKTHROUGH

In 1972, a Göpfert delegation travelled to Düsseldorf for the first time to attend the trade fair for printing and paper, known as DRUPA for short. The company was represented with a machine and information material at a booth belonging to the British machine manufacturer Deritend Engineering. This paved the way for Göpfert‘s first customer in Great Britain. In 1977, during their second visit to the trade fair, which attracted over 1,100 exhibitors and almost 285,000 visitors, the company took the decisive step beyond Europe. After the United Kingdom, Göpfert was now able to win a customer in the United States and gain a foothold overseas. In 1979, the first jumbo slotter with a working width of 4.5 meters was installed at the US company ‘Lawrence Paper Company’.

Deritend Engineering’s trade fair booth at DRUPA 1972, where they established contact with a British customer, laying the foundation for Göpfert’s international business. Part of the booth featured exhibits from the Göpfert company.

1973

RELOCATION TO WIESENTHEID

Karl Franz’s entry into the business not only brought a breath of fresh air to the company but also opened up new sales markets and established the first international contacts. As in previous years, the company’s growth continued in just one direction: upward. A decade after the factory was built, it reached the limits of its capacity. However, no additional land was available in Marktbreit adjacent to the company premises that could be used for expansion. The family therefore decided to relocate, along with their employees, to a new site that would also allow for future growth. They chose Wiesentheid, where they found a suitable 5,000-square-meter plot with expansion potential at a very affordable price. This became the company‘s current site, where a new 1,200-square-metre factory building was completed in 1973.

A bird‘s-eye view of the company premises in Wiesentheid, taken in 1973. Below: The workforce in 1973.

Hans Wolff (left) and Manfred Düll (right) Bottom row (from left to right): Reiner Eitel, Albin Göpfert, Georg Gimmberlein, Nikolaus Natraka, Ernst Schultheiß.

1982

SUCCESS THROUGH COOPERATION

Title pages of various BGM sales brochures from the early 1980s.

Until 1982, Göpfert had exclusively manufactured slitter scorers (KSD, since 1973), eccentric slotting machines (SI, since 1979), boxmakers (SRE, since 1976), stackers (ST, since 1981) and slotters (SL, since 1974). Now the portfolio was expanded. To fulfill a large order, Göpfert entered into a cooperation agreement with Bahmüller. Wilhelm Bahmüller, the company’s founder, had – like Albin Göpfert – established a mechanical workshop in 1945 in his hometown of Plüderhausen, Baden-Württemberg. He quickly gained a foothold in the market and, within a few years, became a leading manufacturer of machines for the corrugated board processing industry. In 1982, the two companies joined forces as congenial partners, forming BGM – Bahmüller und Göpfert Maschinenbau. Engineers from both sides collaborated to develop inline systems for the fully automatic production of corrugated cardboard packaging, i.e. ‘the front section produced by Göpfert is complemented by the closing unit from Bahmüller to form a complete production line’. This cooperation continues to this day. Göpfert not only strengthened its international market position through an expanding machine portfolio but also through strategic cooperation agreements abroad. Founded in 1929, Geo M. Martin Company from Emeryville, California (USA) was one of the world‘s leading suppliers of corrugated cardboard cross-cutting machines at the time, having already set industry-wide standards in the 1960s. Thanks to his entrepreneurial skills, Karl F. Göpfert succeeded in obtaining the rights to distribute the cross cutter in Europe. These developments were important steps for the company in the development of the ‘dry end’ of a corrugated board plant. The dry end comprises the short cross cutter, cross cutter, automatic creasing and cutting machine and computer control.

With Bahmüller as a partner, it was possible to take on larger orders. The two companies now appeared together at trade fairs, for example.

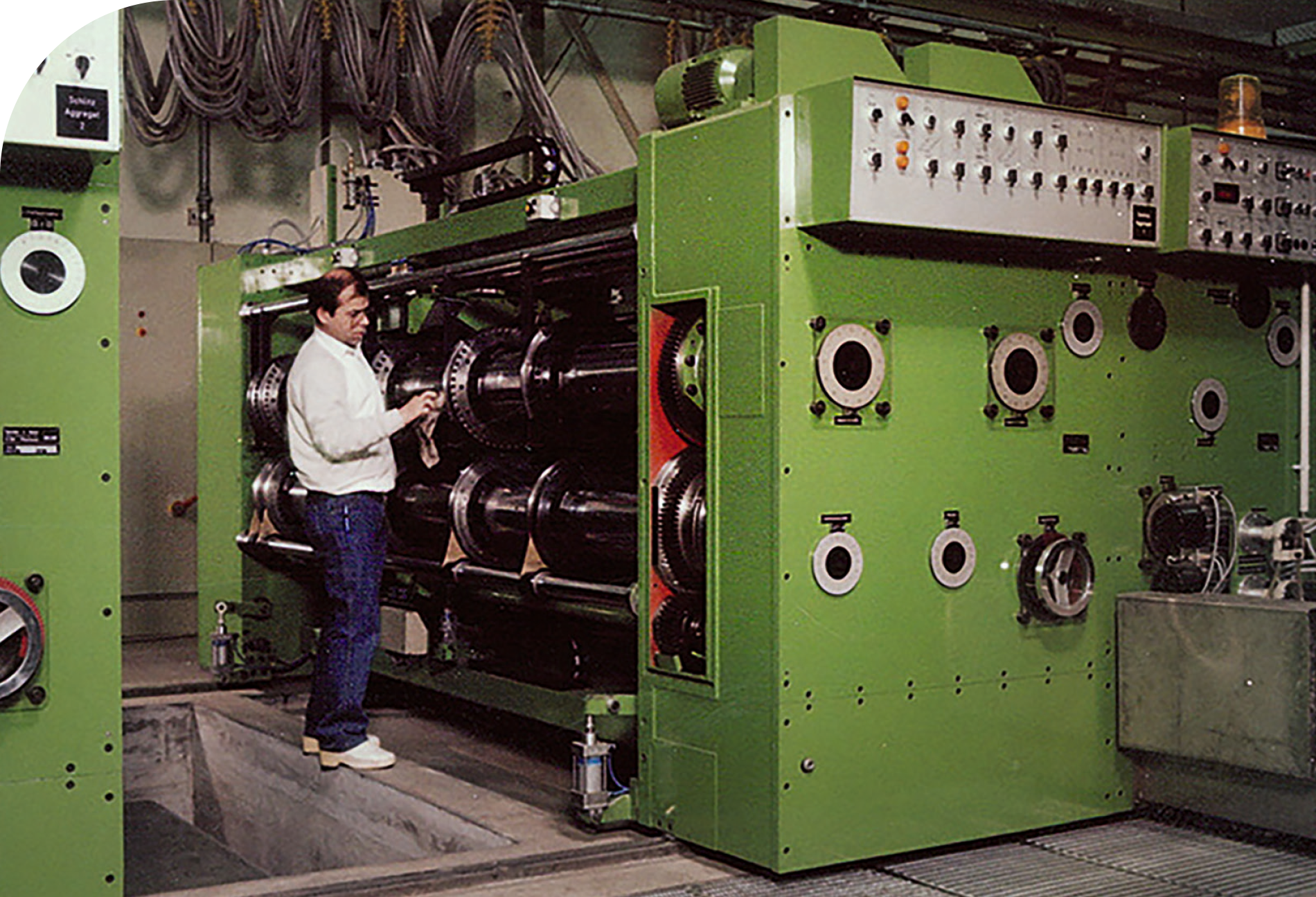

Karl F. Göpfert in 1987 inspecting a machine before it leaves the Wiesentheid factory.

Image of a modern BGM Caseline machine.

1983

GÖPFERT MACHINES ALL OVER THE WORLD

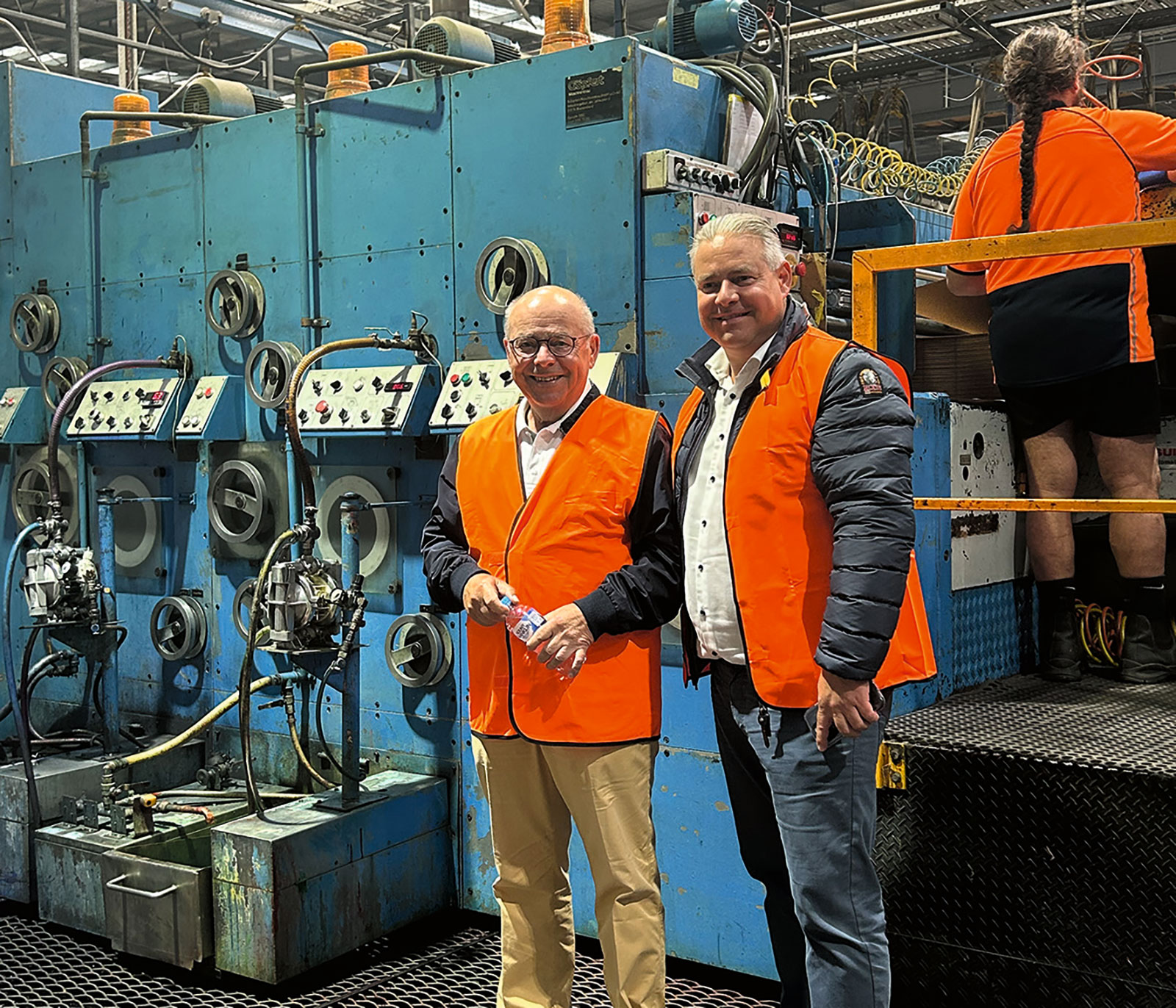

As Göpfert grew, so did its machines – not just in number, but in scale. A prime example was the introduction of the 4.8-meter-wide FPS: a jumbo slotter that set new standards in size and performance. Another key milestone came with the installation of the company’s first in-line rotary die cutting machine. Commissioned by the Franz Gierlichs corrugated cardboard factory in Leverkusen, it exceeded expectations and impressed the customer so much that two more units followed by 1990. Göpfert’s technological excellence was gaining recognition far beyond Germany’s borders. In 1983, after nearly three years of development and construction, the world’s largest flexographic printing slitter at the time—measuring over 5.5 meters in width—was shipped to Australia.

In 1983, a jumbo slotter with a record-breaking width of 5.5 meters was installed for the first time and shipped to Australia. The photo shows the installation team, including Albin Göpfert (center, wearing a light-colored shirt).

Even 41 years later, the machine is still running. In the photo from 2024, Karl F. and André Göpfert are standing in front of the machine during a visit to Australia. Only the color has been repainted by the customer to match their CI.

1989

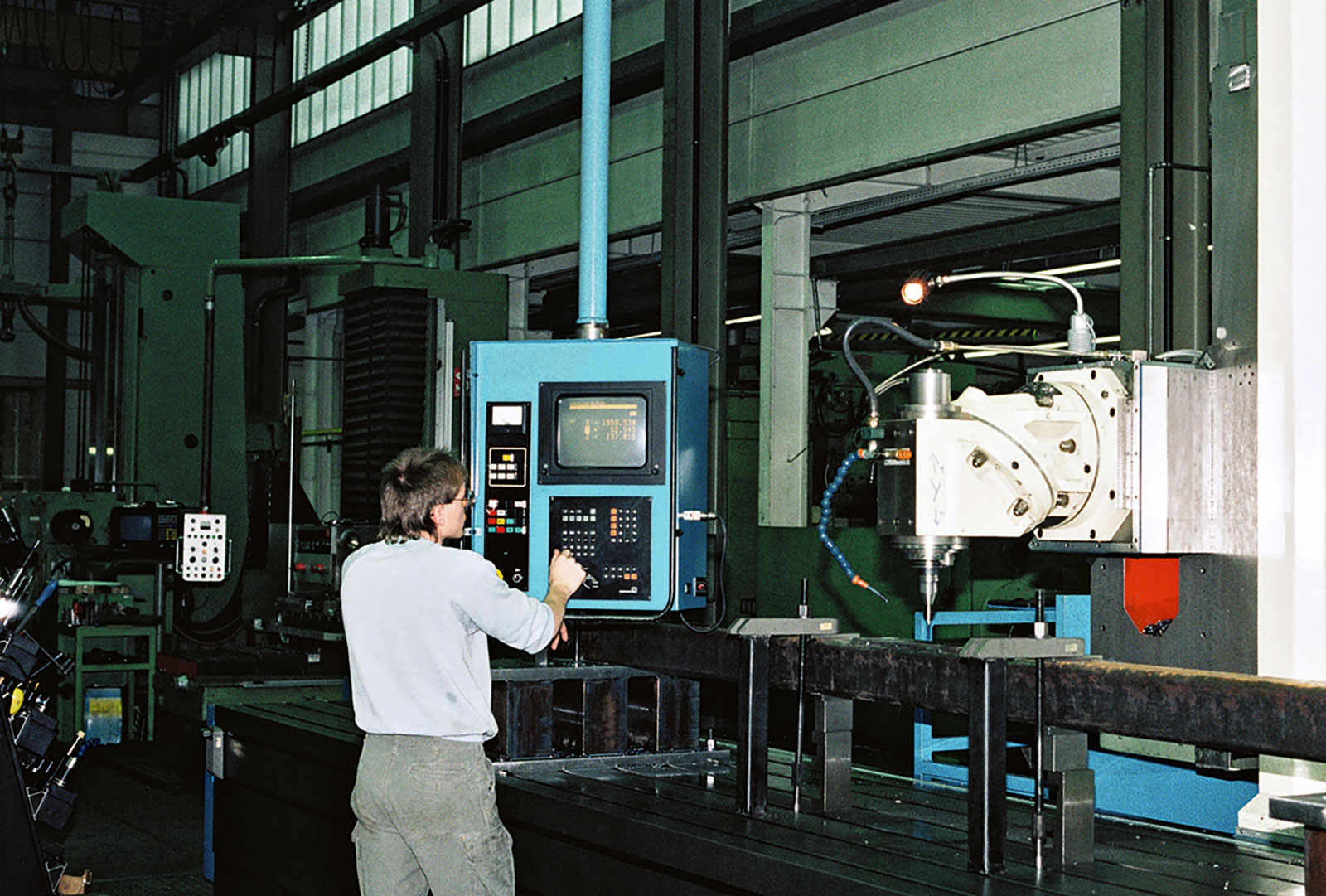

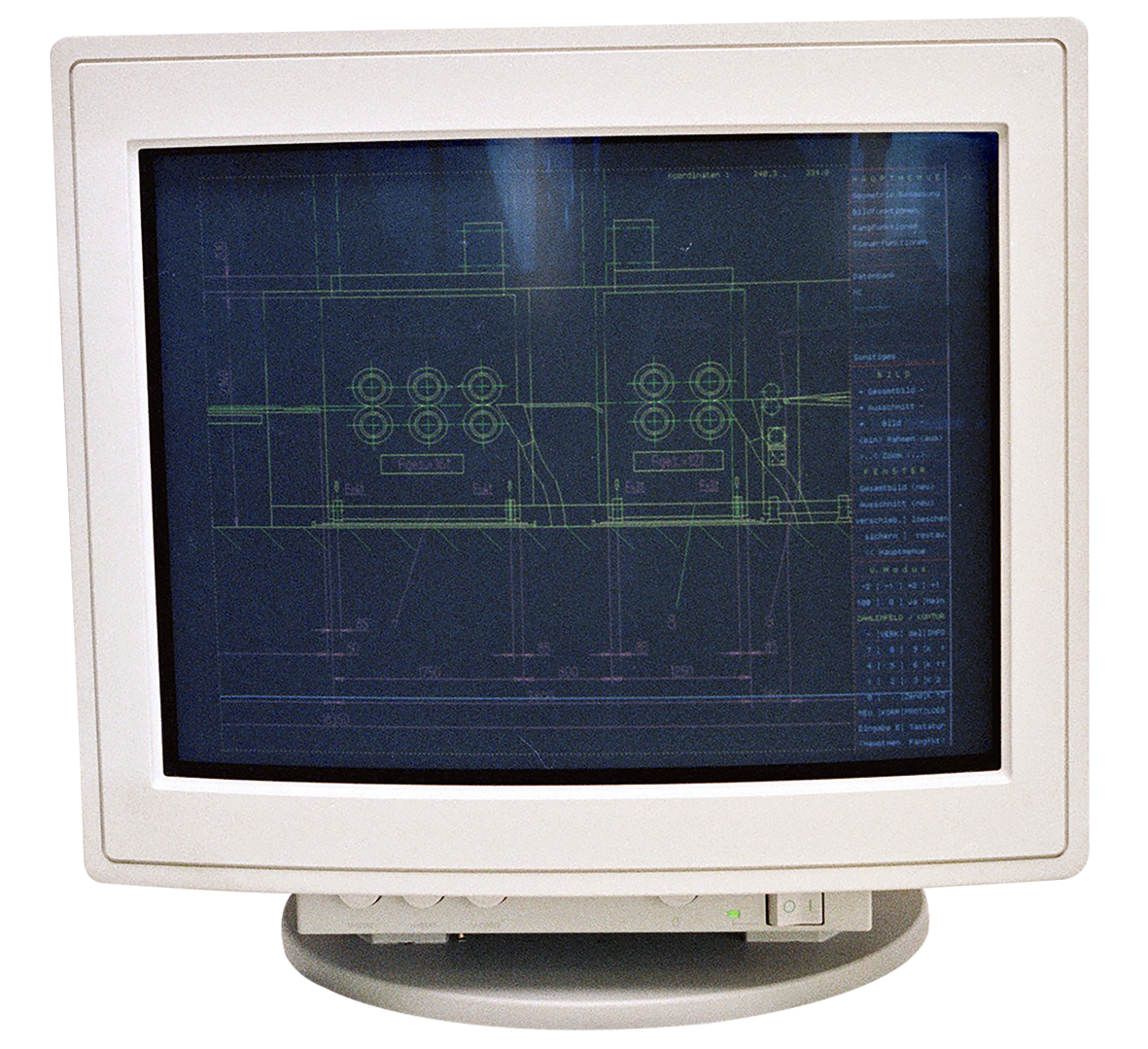

GÖPFERT GOES DIGITAL

The growing number and complexity of machines required not only vast amounts of data but also increasingly sophisticated planning. Early on, the company recognized the need for digital support and implemented advanced IT systems to enhance production planning and process control—commonly referred to as PPS (Production Planning and Scheduling). At the same time, a central database system, or ERP (Enterprise Resource Planning), was established to ensure seamless coordination across departments. A major step forward came in 1989 with the introduction of CAD/CAM systems, which significantly streamlined and professionalized the design and manufacturing of components. By embracing digitalization at an early stage, Göpfert was able to strengthen and sustain its technological edge well into the future.

A photo from the transition phase from drawing board to CAD. Ralf Schiffmann (third from left) as a young engineer talking to technical draftsmen.

1992

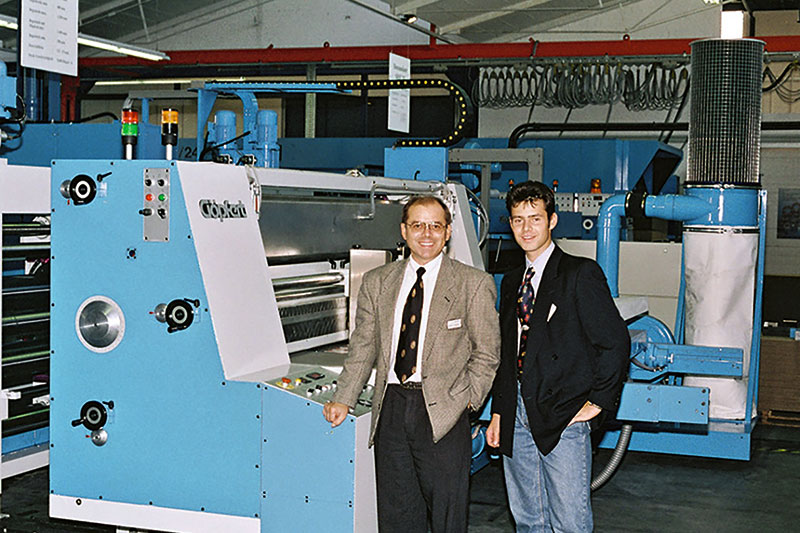

INVITATION TO THE FIRST IN-HOUSE EXHIBITION

In the early 1990s, the company opened its doors to a professional audience for the first time, offering guided tours and presentations that showcased the full scope of its capabilities. The inaugural in-house exhibition was a resounding success and paved the way for many more to follow. Hundreds of guests from around the world – including Western Europe, South Africa, and countries of the former Eastern Bloc – attended the event. The celebrations were crowned with the signing of a contract for the delivery of a 4.8-meter-wide flexo printer inline machine.

The in-house exhibition held in 1992 was a great success, drawing visitors from around the world to Wiesentheid. Alongside informative presentations, a varied entertainment program ensured an enjoyable experience for all attendees. Pictured: Karl F. Göpfert with his son André in front of the Euroslotter, 1992.

Another technical masterpiece was the development of the ‘Evolution’ in 1996, which continues to set standards today.

1993

BEST IN ITS CLASS

The 1990s were marked by the development of new machine types that went beyond the limits of what had previously been possible. In 1993, Göpfert introduced a mini version of the SRE boxmaker. It is used for small formats and series in the processing of corrugated cardboard and ensures cost-effective production even with small quantities. In 1996, Karl F. Göpfert initiated another sensation: the introduction of a servo-driven rotary die cutter. Its apt name was ‘Evolution’. This masterpiece of technology became a blockbuster and is still state of the art today. At first, the machine worked so fast that it simply overwhelmed the sheet separators that had been standard until then. Göpfert subsequently developed the ‘EVO-Stack’ sheet stacker, which was able to keep pace with the Evolution and set new records in production in terms of performance amplitude. In 1999, a new chapter in the history of flexographic printing presses was opened. The ‘Impression’, the first post-print machine, lived up to its name: it made a powerful impression on customers. Perhaps because this model received so much acclaim, the second generation of the series, which followed in 2003, was named ‘Ovation’. It also established itself as the standard in its class. Anyone looking for the ultimate in printing accuracy and equipment at that time printed corrugated cardboard with a Göpfert Ovation.

Since 1993, the little sister (SRE Mini) of the Boxmaker SRE has made small-scale production more economical.

2000

CONSISTENCY AND CHANGE

In 2000, Göpfert celebrated its 50th anniversary. The company was honored during a committee meeting of the Würzburg-Schweinfurt Chamber of Industry and Commerce, held in Wiesentheid. Göpfert Maschinenbau GmbH continued its dynamic growth: by the turn of the millennium, the workforce had increased to 180 employees, working in a 6,000-square-meter facility. Among them were 20 apprentices training in skilled trades such as metalworking, electrical engineering, technical drawing, and commercial occupations. The 2000s also marked a comprehensive brand relaunch. The entire corporate identity – including brochures, the website, and advertisements – was redesigned and modernized. In addition, the company launched its retrofit program, aimed at upgrading older machines with modern technology. As Göpfert puts it: “The iron of the machine lasts a hundred years – but it needs the right software to run, now and in the future.”

Cover of the first in-house magazine, Innovations, which was published starting in 2005. In 2011, it was succeeded by Wellenwerk.

Göpfert invests in young talent through its own training programs. This 2005 photo shows apprentices alongside their trainers.

2005

ENTRY OF THE THIRD GENERATION

André and Esther Göpfert after their appointment as Managing Directors in 2005.

In 2005, the company invested in a much-needed additional office building. That same year, Esther Göpfert, who had joined the company in 1993, and her brother André, who had come on board in 2002, became managing directors. This allowed the family to distribute the growing number of tasks and responsibilities across several shoulders. Esther Göpfert has since become the backbone of the company, handling all the ‘non-technical challenges’ with tireless dedication and determination. She oversees the finances, ensures smooth and efficient administrative operations, and manages all personnel matters. André Göpfert, having gained valuable experience in the USA, recognized a significant market gap for attractive printed packaging. This sparked his passion for flexographic printing, earning him the title of ‘printing guru’ at Göpfert. To this day, all printing-related issues are directed to him. His love for the USA also led him to successfully establish the company’s presence there. André was key to the development of the ‘Ovation’ high-graphics machine. Karl F. Göpfert continues to pursue his passion for machine development and heads the technical department. Siglinde Göpfert remains responsible for purchasing.

2009

NAVIGATING SMOOTHLY THROUGH THE GLOBAL FINANCIAL CRISIS

In 2009, a real estate bubble in the USA triggered a global financial crisis with far-reaching consequences, some of which had a devastating impact on the Main-Franconia economic region. However, thanks to its flexible structures and the adaptability of its employees, the company was able to navigate the crisis with ease. This achievement is especially impressive considering that many competitors were forced out of the market due to the economic downturn. By 2010, the company had even resumed overtime in its production halls to handle a renewed surge in orders.

The completion and delivery of a 100-ton machine to Saudi Arabia was a truly exceptional order. It broke all records in terms of speed, specifications, and volume.

RECORD SALES ON THE WAY TO BAVARIAS'S FOREFRONT

By 2012 at the latest, the crisis in the industry had been fully overcome: global demand for corrugated board processing machines exceeded all expectations. As a result, one sales record followed another in the years that followed. In order to keep pace with the company’s development in terms of construction, a neighboring property was acquired and further expansion took place there. A glance at the number of employees makes it clear why this step was important: Göpfert now employed over 300 people. By then, the company had long been one of Bavaria’s economic leaders, operating at the peak of its success. In 2017, the company was awarded the ‘Bayerns Best 50’ award by the Bavarian Ministry of Economic Affairs for the first time – and again in 2022. The idea behind the award was explained by Minister of Economic Affairs Hubert Aiwanger at the 2022 ceremony: “What unites the award winners is their ability to significantly improve both turnover and employee numbers over the last five years. With these economic achievements and the new jobs created, they have contributed to the advancement of the Free State of Bavaria. While overshadowed by large German companies, these winners have made exceptional contributions, particularly through their long-standing commitment to vocational training.”

In 2022, the Wiesentheid-based company received the award for the second time.

In 2017, the mechanical engineering company was honoured by the Bavarian state government for its achievements.

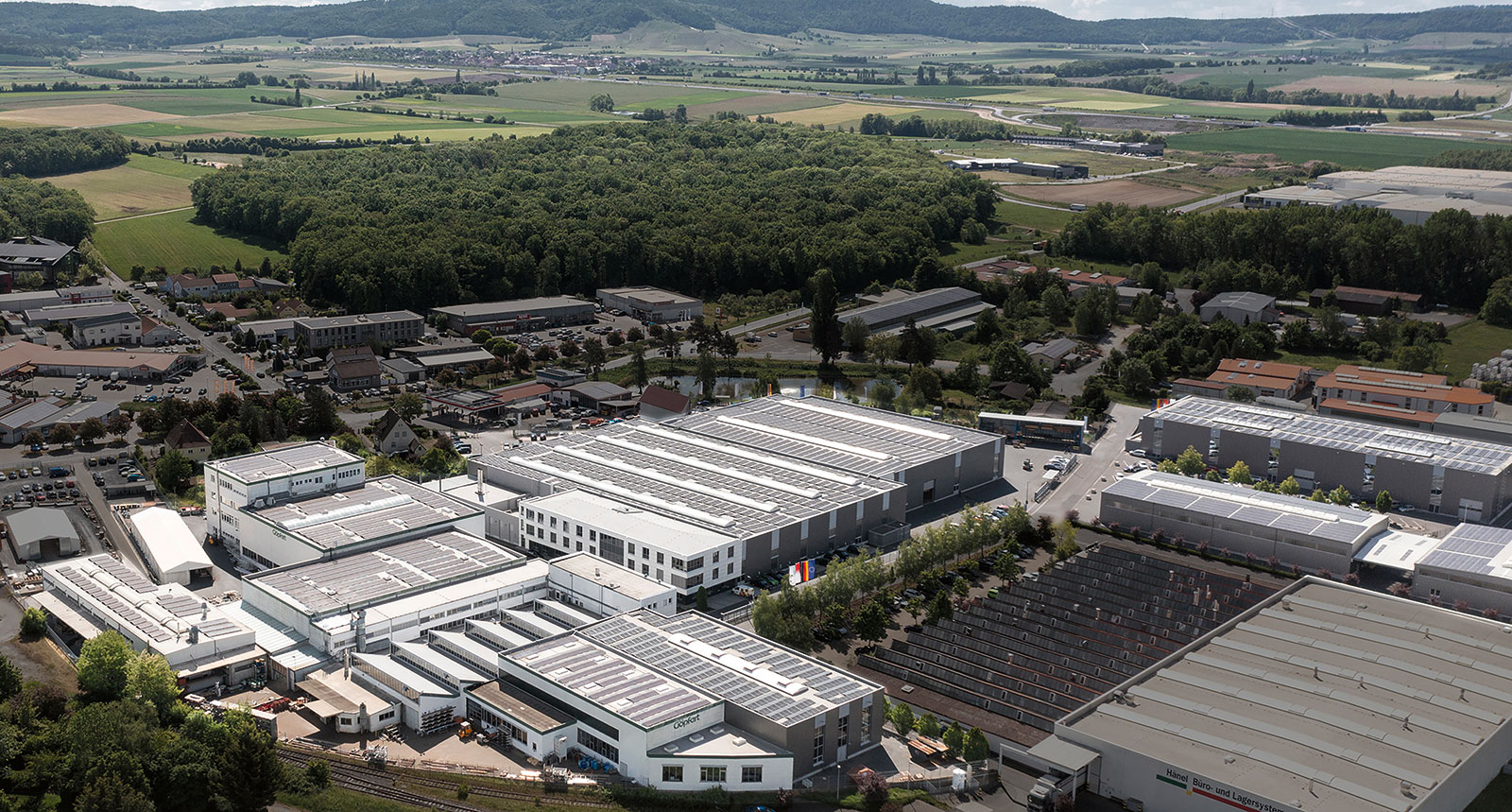

2015

FULLY OVERHAULED

The expansion of the company to include a computer-controlled logistics warehouse, two assembly halls, and an administration building marked a significant milestone in its history, with a total investment of over 15 million euros. In this context, André Göpfert referred to it as a “magnificent achievement” back in 2015. The first step in this project was the demolition of an existing building in the summer of 2014, followed by the construction of two modern warehouses covering a total area of 2,600 square meters. Simultaneously, over 100 parking spaces were created for employees. At the end of 2014, construction began on two additional halls, totaling 9,000 square meters. The expansion was completed in early 2017. In addition to the two warehouses – including a fully automated small parts warehouse with 8,316 container spaces and an automatic high-bay pallet warehouse with 1,708 spaces – a final assembly hall and a new sales and training center were also built. The old hall structures, which had been in place for decades, were completely redesigned and rebuilt. Optimized logistics now allow for higher production speeds and faster deliveries. The assembly capacity has increased to accommodate up to twelve printing and die cutting machines, which can now be assembled simultaneously. Additionally, solar collectors and a modern wood chip heating system have made the company largely energy self-sufficient.

Cover page of the periodical ‘Wirtschaft in Mainfranken’ (Economy in Main-Franconia), the official magazine of the Würzburg-Schweinfurt Chamber of Industry and Commerce. In 2017, it featured a profile of the Göpfert family, giving readers extensive insights into the company.

View of the modern logistics hall with high-bay warehouse, where everything is digital. Modern warehousing and distribution methods enable efficient processes and are just as exemplary as the technical machine developments from Göpfert.

BECOMING A FULL RANGE SUPPLIER

Material handling system from subsidiary Corrpal Systems AB in combination with a Göpfert machine.

In 2021, Göpfert Maschinen GmbH became the majority shareholder of Dücker Corrpal AB, based in Ystad near Malmö, Sweden, a leading specialist in breakers and palletizing systems. In 2022, Göpfert was able to acquire 100 percent of the Swedish company. This made the company a full-range provider of corrugated cardboard processing systems. Today, in its 75th year of business, the Göpfert Group employs around 550 people. With its rich history, it stands as one of the longest-established family-owned companies in the Mainfranken region.Göpfert continues to grow, and the group remains in excellent shape. With the ongoing rise of e-commerce in Germany, across Europe, and beyond, corrugated packaging is becoming increasingly important. As online retail expands rapidly, so too does the global demand for effective and efficient packaging solutions. Despite its continued success, the company based in Wiesentheid keeps a close eye on market trends and is actively working to diversify its portfolio. In addition to favorable economic conditions, Göpfert’s success rests on another key foundation that has defined the company from the very beginning: the strength of the family. Their unity has always ensured long-term continuity – and the Göpfert family is committed to preserving that legacy well into the future.